In the fast-paced world of solar energy development, time and return on investment are everything. Every day lost to complex, labor-intensive installation is a day of lost energy production and revenue. For project developers and EPC contractors, the challenge is clear: how to accelerate project timelines without compromising on the foundational stability of the installation—while also keeping logistical and operational costs under control?

This is where Tripod Solar Mounting Systems redefine the game. Choosing tripod mounting isn‘t just about selecting a racking component; it‘s a strategic business decision for unparalleled efficiency and profitability.

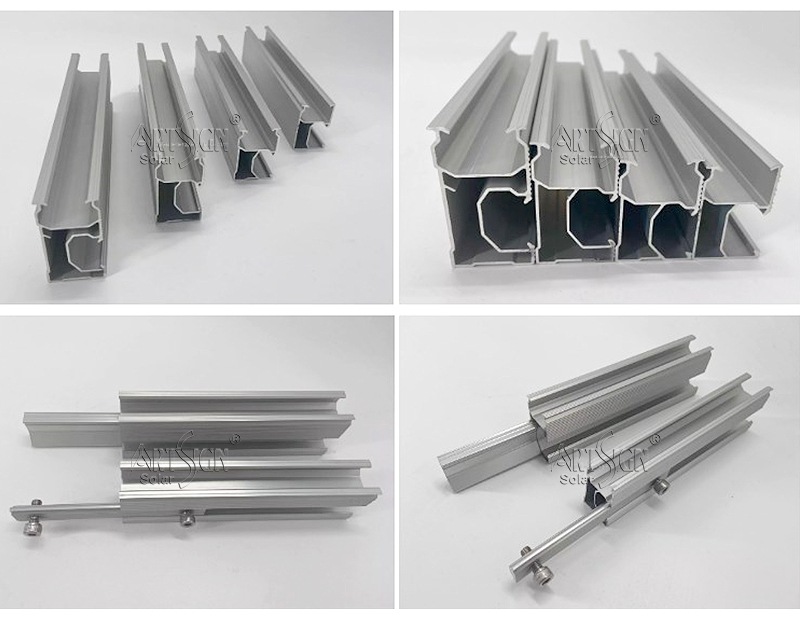

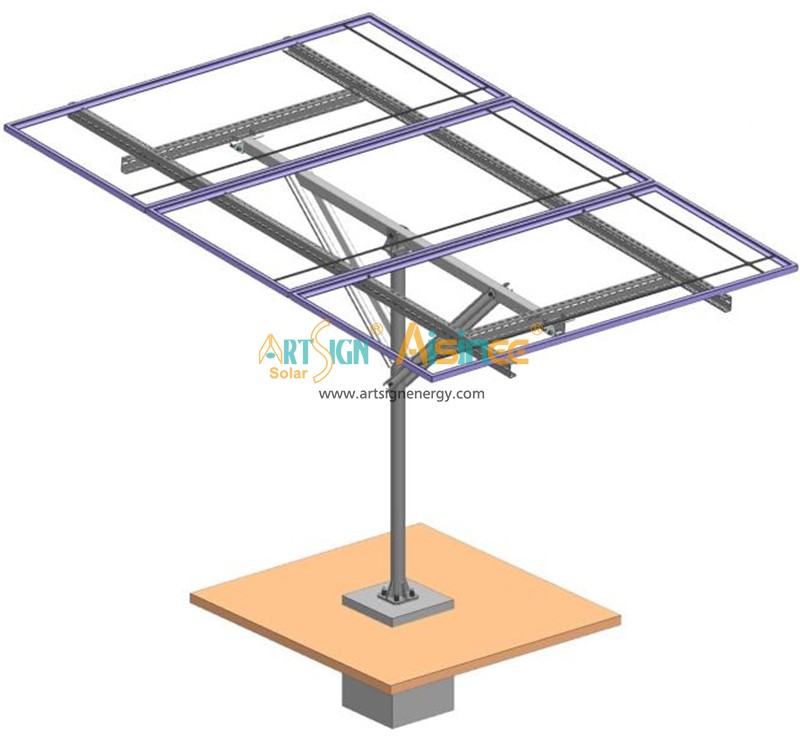

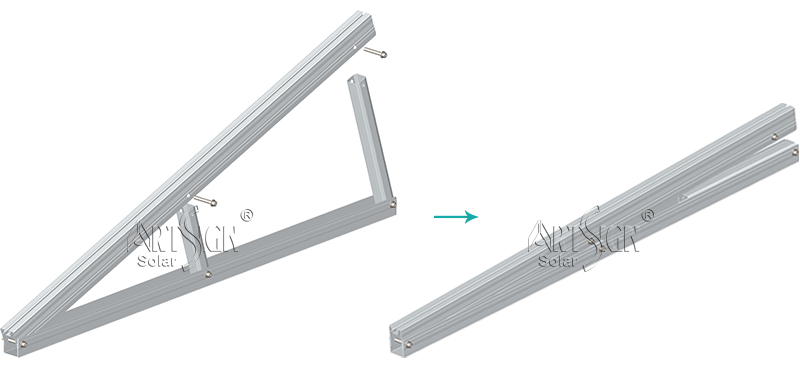

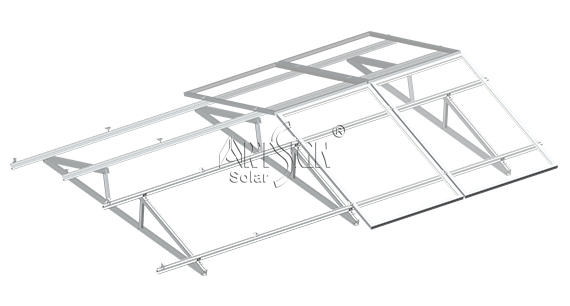

One of the significant advantages of our U Beam triangle kit solar mounting structure lies in its meticulously designed efficiency --this is not only reflected in the installation process, but also during transportation. The U-shaped groove design enables the entire support structure to be pre-assembled in the factory, and then it can be folded and placed flat for transportation. This logistics design directly leads to a reduction in project transportation and storage costs, and the savings effect can be seen from the very beginning of the selection of the support structure.

Engineered for Excellence: The Core Advantages of the U Beam Triangle Kit

1.Unmatched Versatility and Adaptability

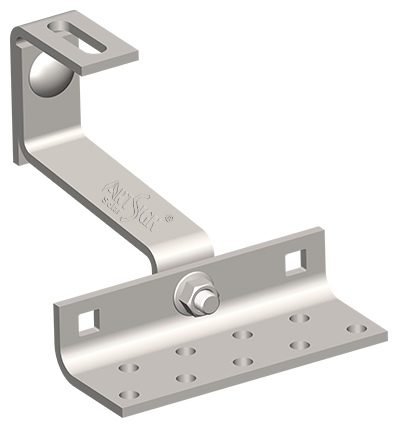

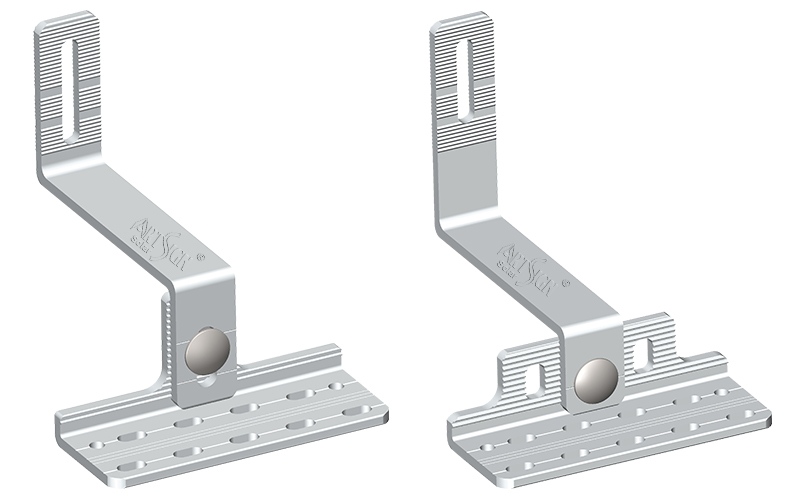

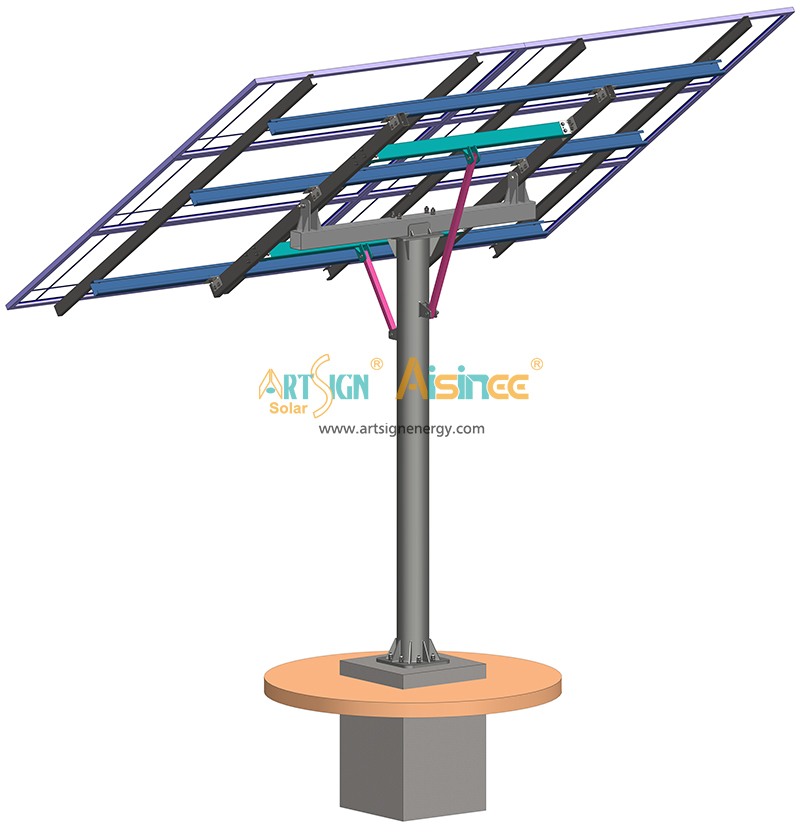

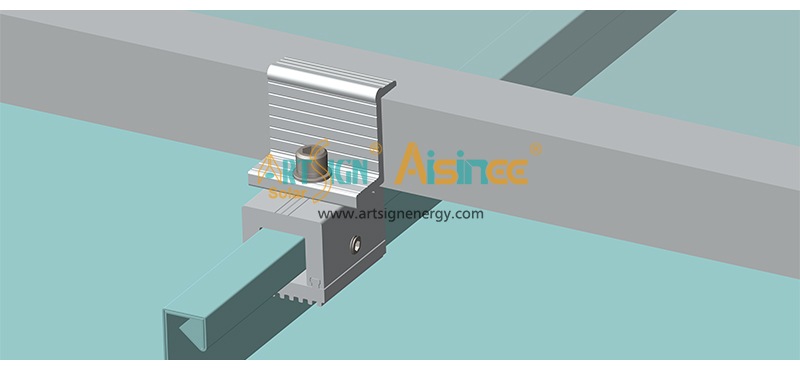

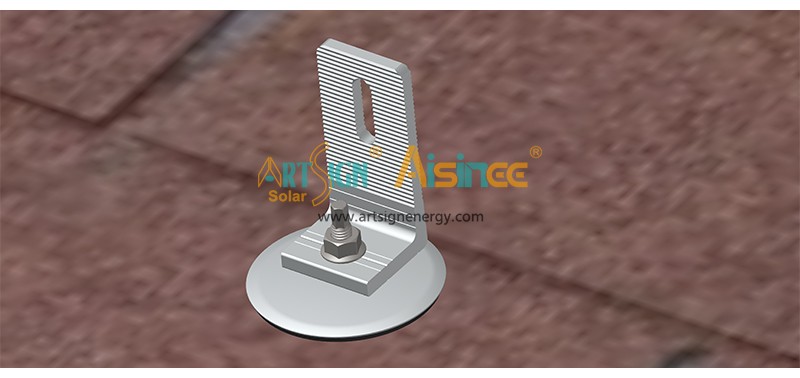

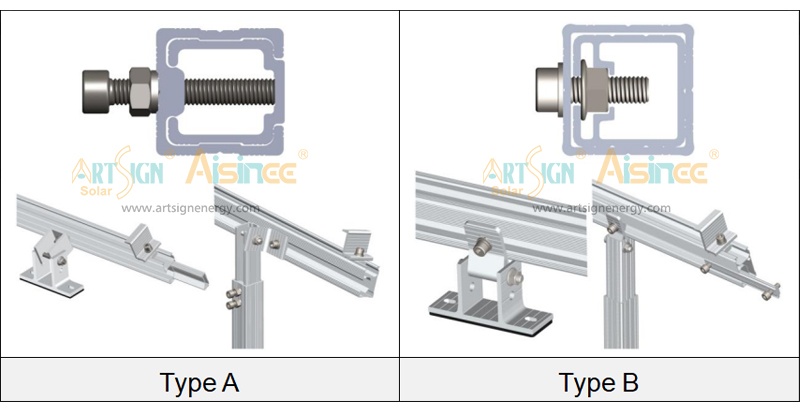

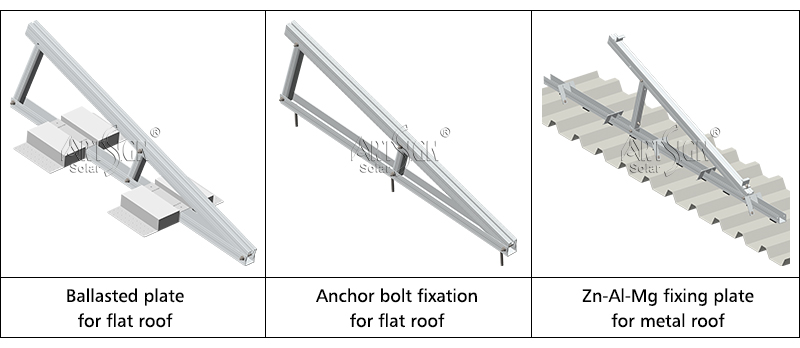

Highly Accommodating to Terrain: Exceptionally suited for uneven, sloped, rocky, or otherwise challenging ground conditions. It eliminates the need for extensive grading, significantly reducing pre-construction difficulty and cost. Roof-Friendly Solution: On rooftops (particularly commercial flat roofs), the tripod system enables ballasted installation, minimizing or completely avoiding roof penetration. This protects waterproofing layers and simplifies approval processes. Our U Beam Triangle Kit is the simple, smart foundation for almost any rooftop solar project. It can be used as flat roof solar mounting brackets, also the metal roof solar mounting structure. When it install on the flat roof, It has 3 fixation methods.

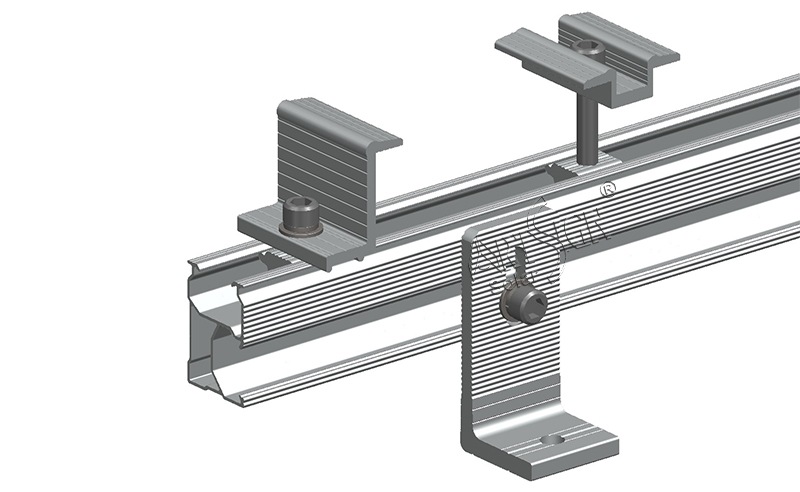

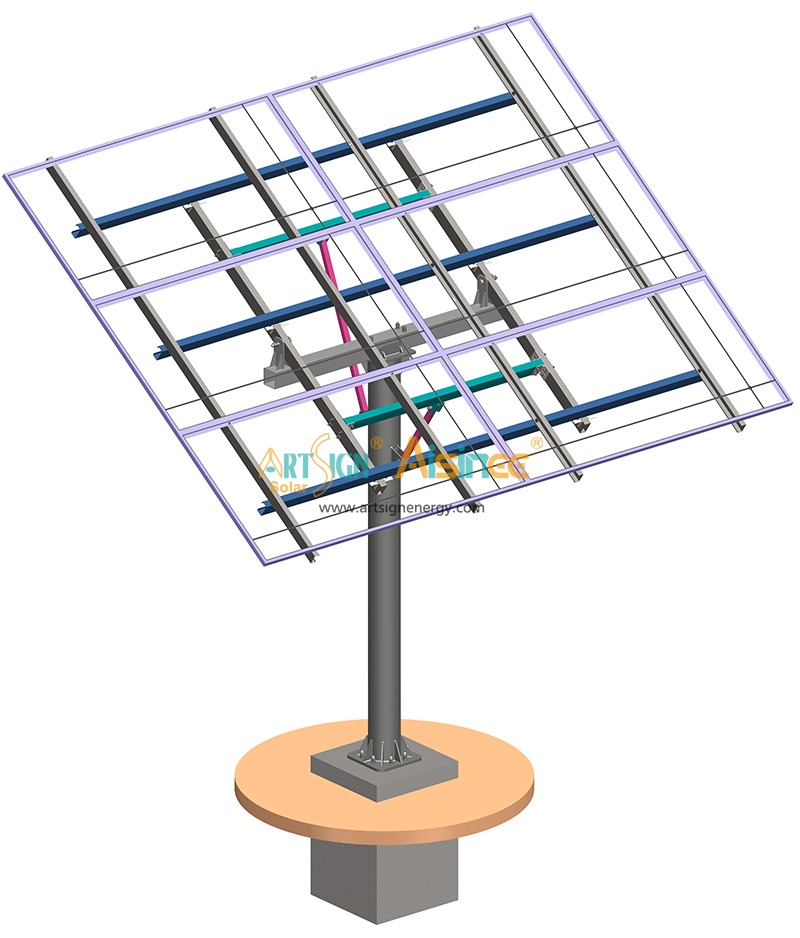

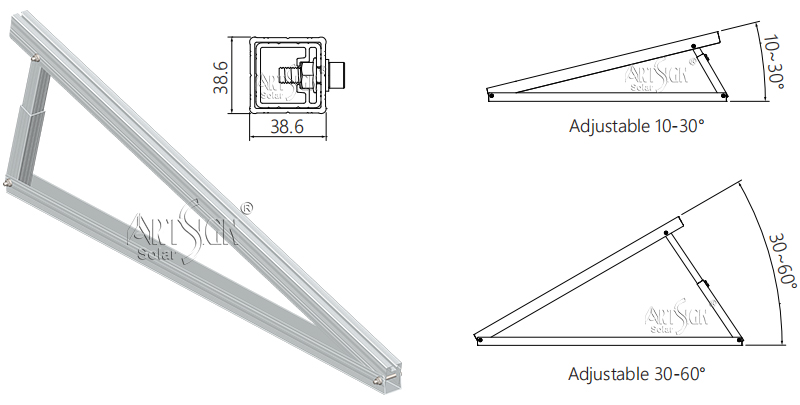

Triangular Structural Stability: The classic tripod geometry provides exceptional resistance to wind and snow loads, along with outstanding structural integrity. This ensures safe and reliable system performance throughout its entire lifecycle. Independent Adjustability : Each support unit can be adjusted independently in both leveling and height. This allows for easy adaptation to minor ground irregularities or roof unevenness, guaranteeing precise installation and a sleek, uniform appearance for the entire array.

Item

Specification & Description

Product name

U Beam Triangle Kit

Fixed Tilt Angles

Fixed customized degree or adjustable(10-15,15-30)degree

Applicable Module

Suitable for both commercial and residential concrete flat roofs ,metal roof and the ground.

Certificate Australia

AS/NZS 1170.2, SGS, TUV, CE

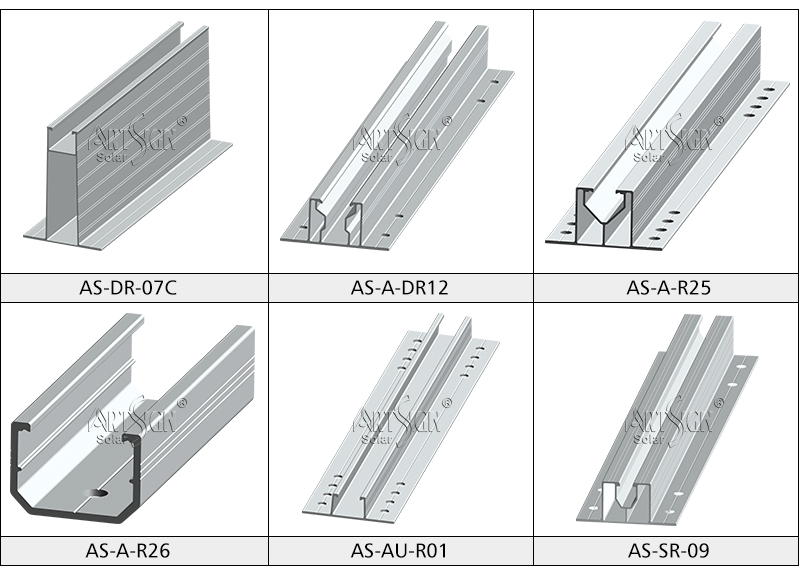

Material

Anodized aluminum Al6005-T5

Service Life

20-25 years

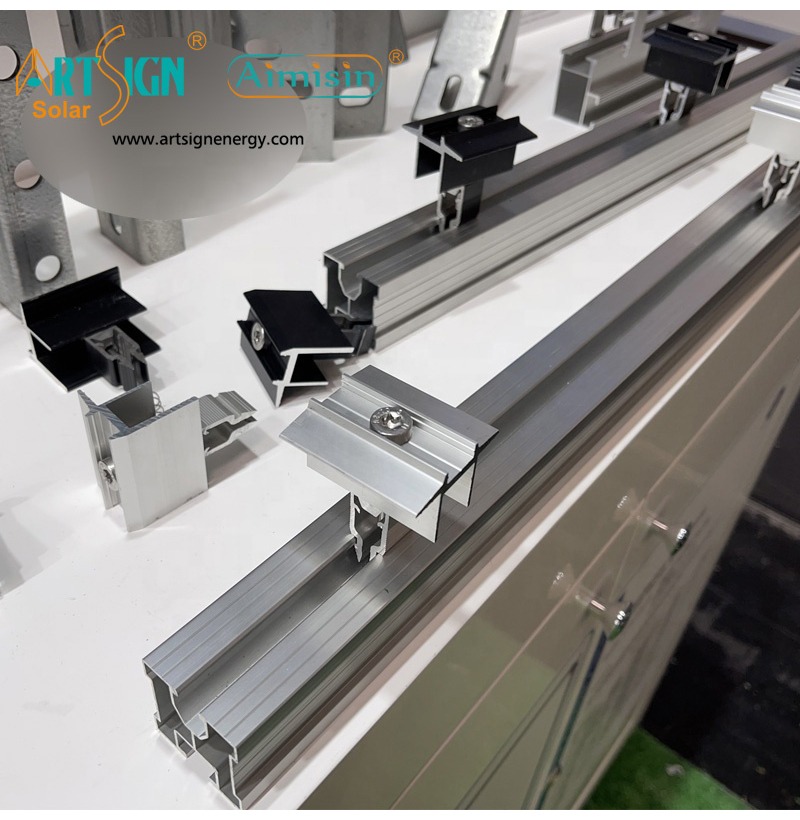

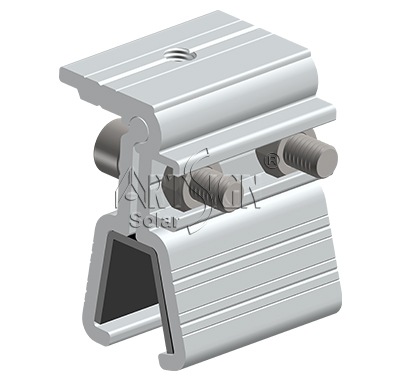

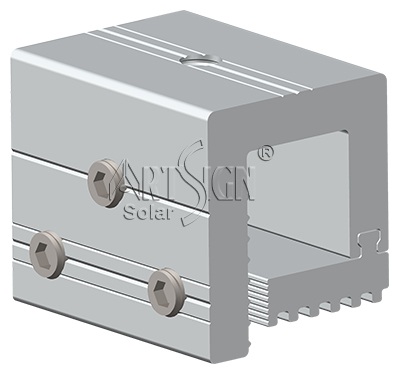

With the fundamental question of “how to secure it to the roof” solved, the true strength of the U-Channel Triangle Kit is revealed in its versatility at its attachment points. Acting as a standardized, adaptive platform, it unleashes unparalleled design freedom by seamlessly supporting three primary installation methods—allowing your project to break free from layout constraints and optimize for performance, speed, or density.

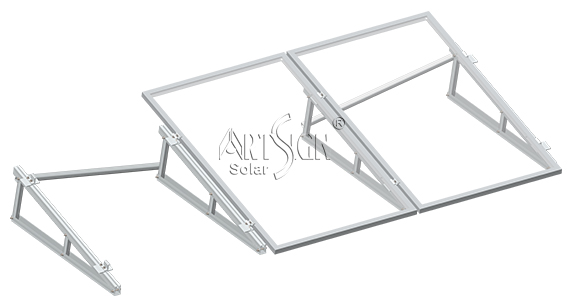

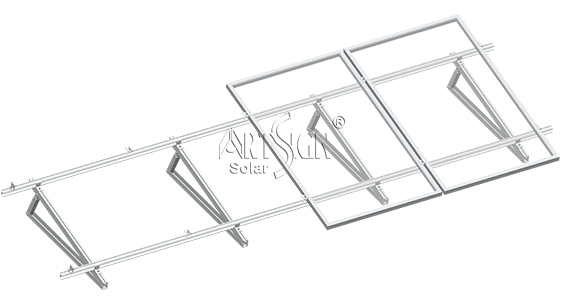

Without Rails: For a faster, cleaner install, mount panels directly onto the kits to save time and costs.

With Rails: It’s strong enough with rail to resist big wind and snow load.

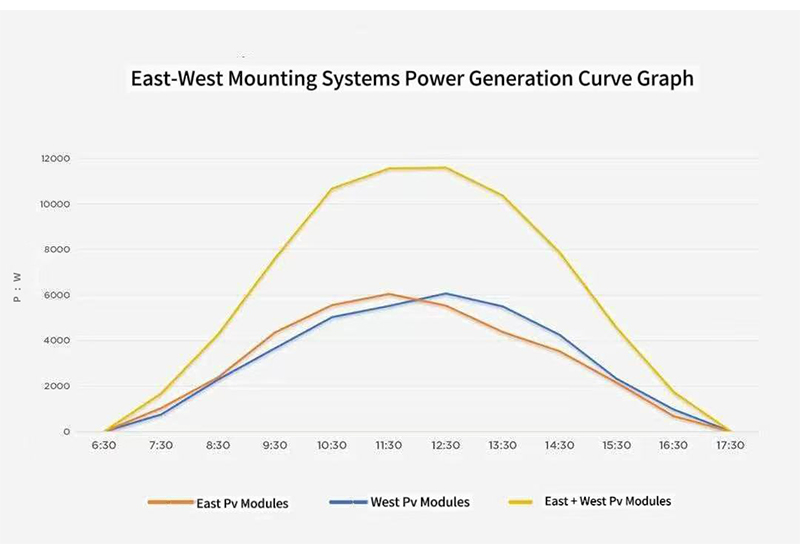

East-West Layouts: By placing modules back-to-back, clearance for module shading can be avoided, more modules can be places in the same area, and can increase the power production.

The Future of Roof-Mounted PV and Our Forward-Looking Solution

The rooftop solar market is rapidly evolving, with solar roof mounting systems advancing toward lightweight design, intelligent adjustment, and higher integration. Future roof mounts will need to be lighter to reduce structural load, while potentially incorporating smart tracking systems that adjust tilt in real time based on sunlight—maximizing energy yield from every ray of sunlight.

Our U Beam Triangle Kit is designed precisely for this future. Its U-shaped profile ensures superior structural stability while optimizing material use and reducing weight, thereby minimizing the load on rooftops. More importantly, the system’s modular design and independent three-dimensional adjustability create a flexible platform ready for future upgrades—whether for adding intelligent tracking actuators or adapting to new, larger-format solar panels. Choosing the U Beam means not only selecting a robust mount, but investing in a forward-looking solution that evolves with technology to protect and enhance your long-term return on investment.

For any inquiry of solar panel mounting system, pls contact us, E-mail: sales@artsign.net.cn, Whatsapp / Wechat / Skype:+008618030235875, thanks.