Driving Solar Innovation: Landpower Shines at SNEC PV POWER EXPO as China Leading Solar Mounting Systems Manufacturer

The solar mounting systems industry witnessed significant developments at the 18th SNEC International Photovoltaic Power Generation and Smart Energy Exhibition & Conference held June 11-13, 2025, in Shanghai, demonstrating the critical role specialized manufacturers play in supporting global solar deployment. With mounting systems representing a crucial component in the solar value chain, and leading manufacturers now exceeding 800 MW monthly production capacity supported by regional warehousing networks, the industry increasingly recognizes the importance of partnering with established suppliers who combine technical expertise with proven manufacturing capabilities. Among the companies showcasing advanced solutions at this year's expo, Xiamen Landpower Solar Technology Co., Ltd. distinguished itself as a China Leading Solar Mounting Systems Manufacturer, demonstrating 12 years of specialized expertise across diverse mounting applications and international markets.

SNEC PV POWER EXPO: Global Solar Industry's Premier Showcase

The SNEC exhibition has evolved into the world's most influential photovoltaic industry platform, expanding from 15,000 square meters in 2007 to over 380,000 square meters in 2024, attracting more than 3,600 exhibiting companies from 95 countries. This remarkable growth trajectory reflects the exhibition's role as a critical networking hub where industry leaders, technology innovators, and market participants converge to shape the future of solar energy.

The 2025 edition featured comprehensive displays across multiple technology segments, including mounting systems, production equipment, energy storage technologies, inverters and power supply solutions, materials, and solar cells & panels. The exhibition's focus on mounting systems underscored their growing importance in solar project success, as industry participants increasingly recognize that mounting infrastructure directly impacts installation efficiency, operational reliability, and long-term project economics.

Technology Innovations and Market Trends at SNEC 2025

Industry leaders at SNEC 2025 unveiled significant technological advances that address evolving market requirements and performance expectations. Multiple leading companies revealed new high-efficiency module products, such as JinkoSolar's Tiger Neo 3.0 module with 670W/24.8% efficiency, scheduled for mass production in the second half of 2025, while partnerships like Skyworth Solar's collaboration with Aikosolar demonstrated the global launch of All Back Contact technology.

The exhibition highlighted the industry's focus on efficiency optimization and cost reduction across the entire solar value chain. Mounting system manufacturers showcased advanced solutions that accommodate next-generation panel technologies while simplifying installation procedures and reducing deployment costs.

Despite challenging market conditions that led to thinner crowds as many manufacturers scaled back spending after two years of losses, the exhibition maintained its position as the industry's primary platform for technology demonstration and business development. The broader PV industry experienced stronger-than-expected demand in the first half of 2025, largely driven by China's installation rush, though demand began showing signs of weakening in the second half.

Mounting Systems Market Dynamics and Growth Drivers

The global solar mounting systems market demonstrated robust growth momentum, with worldwide sales reaching $16.28 billion in 2024 and projected to hit $28.4 billion by 2031, expanding at a 7.9% CAGR. This growth reflects increasing solar deployment across residential, commercial, and utility-scale applications, each presenting distinct mounting system requirements.

Fixed-tilt systems maintain dominance in ground-mounted and distributed applications across China due to structural simplicity, minimal maintenance requirements, and lower initial investment costs. However, the industry continues innovating across multiple mounting technologies to address diverse application requirements and environmental conditions.

The competitive landscape features established players including Arctech, Clenergy, Convert Italia, K2 Systems, and AEROCOMPACT, which contribute to 40% market share collectively. Many manufacturers are developing methods to optimize performance for bifacial solar panels, reflecting the industry's evolution toward enhanced energy capture technologies.

Landpower's Market Position and Technological Leadership

Within this dynamic exhibition environment, companies that demonstrate comprehensive capabilities across product innovation, manufacturing excellence, and customer support attract significant attention from industry participants and potential partners. Landpower Solar's presence at SNEC 2025 showcased their evolution into a Best Solar Mounting Systems supplier through systematic investment in engineering capabilities and production infrastructure.

Advanced Product Portfolio and Technical Innovation

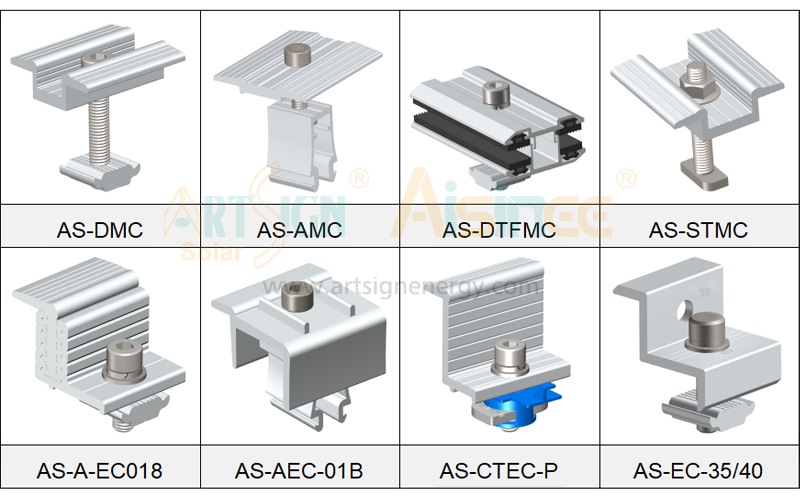

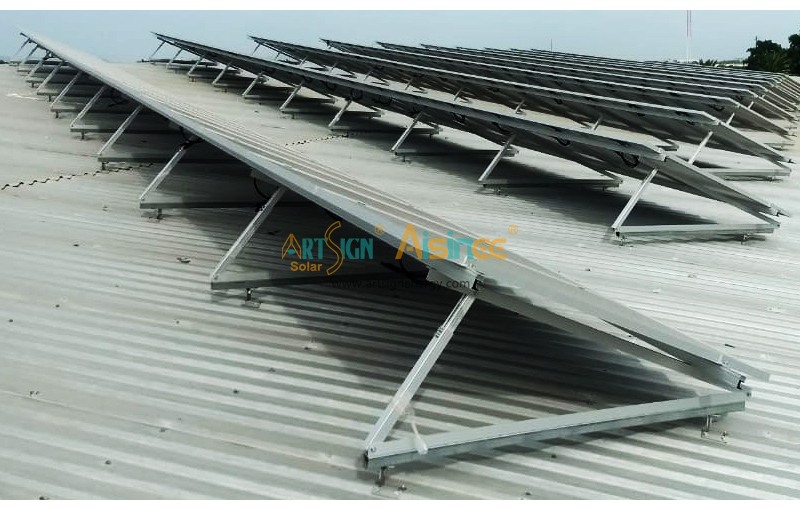

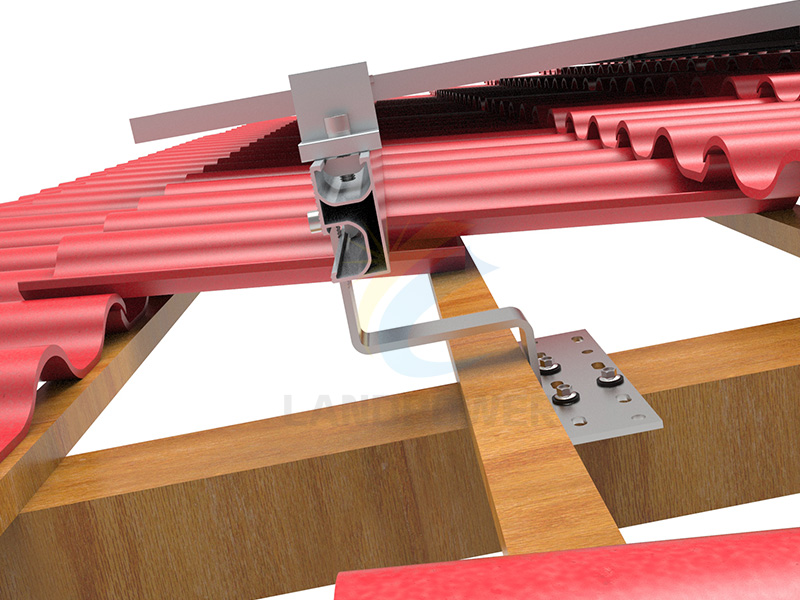

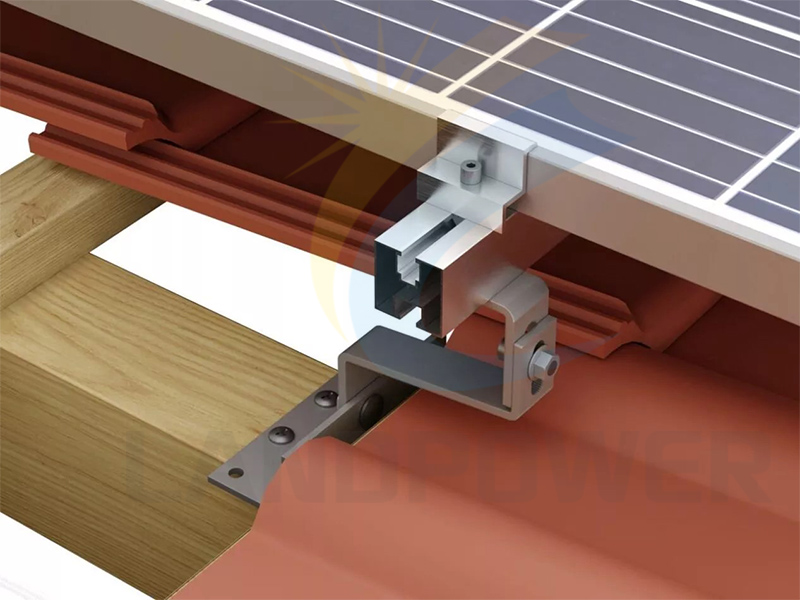

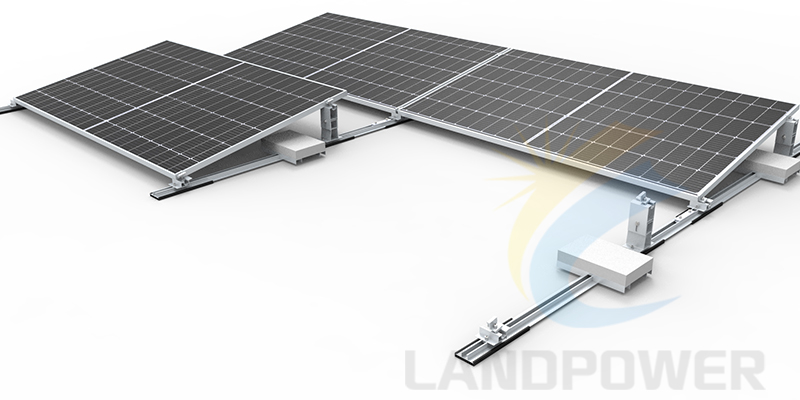

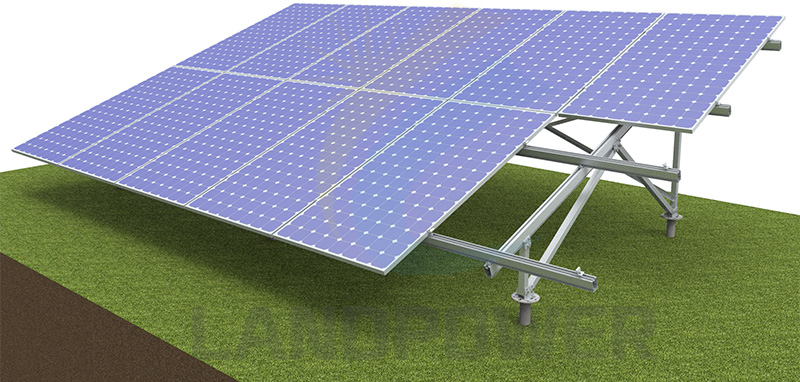

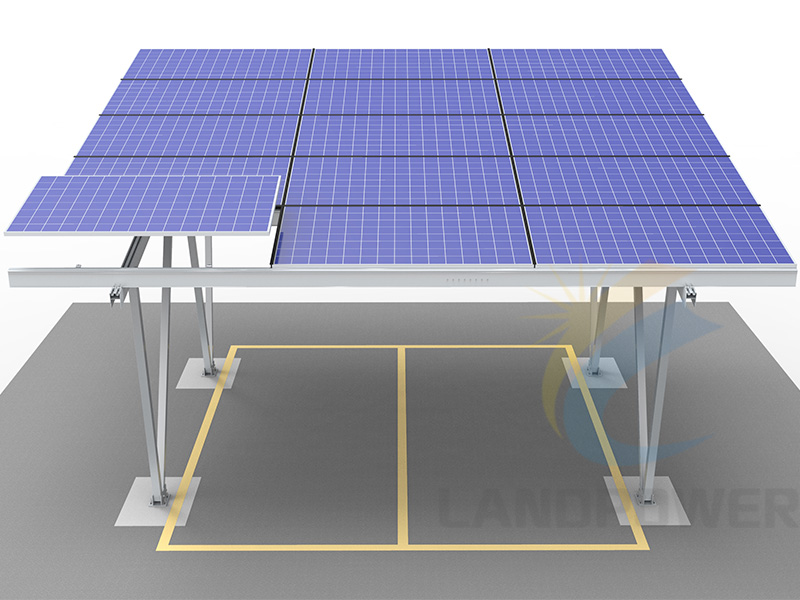

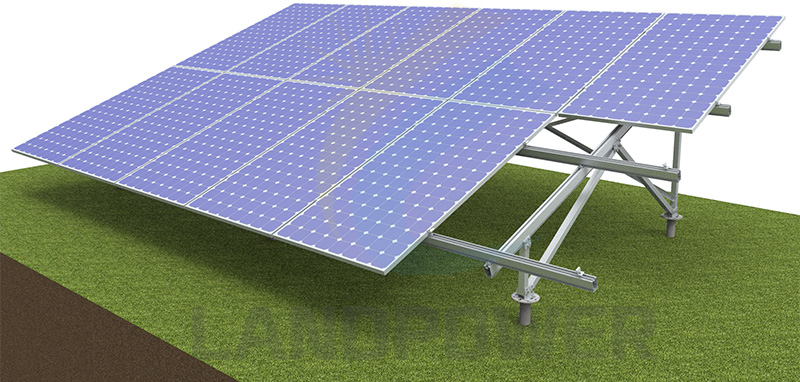

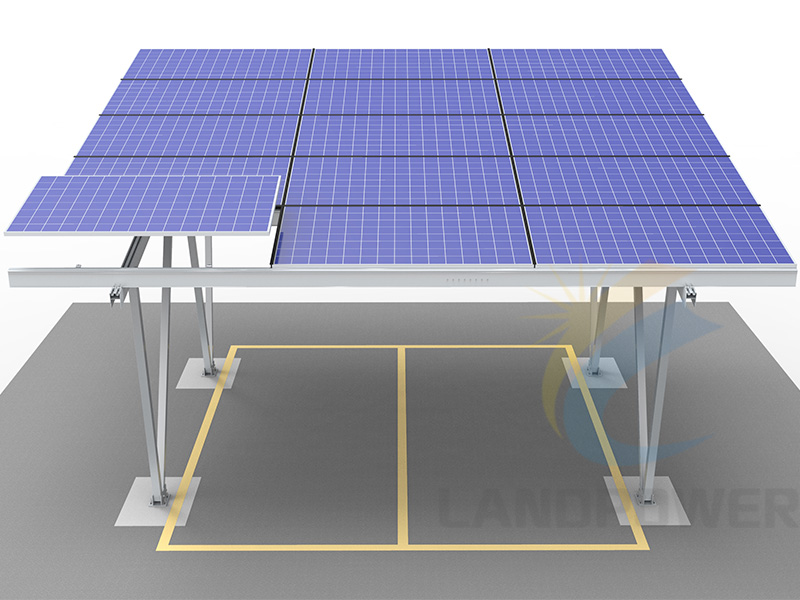

Landpower's exhibition presence highlighted their comprehensive mounting system portfolio that addresses multiple application segments and installation environments. Their product range encompasses ground mounting structures, flat roof systems, pitched roof solutions, and specialized applications including carports and BIPV installations.

The company's ground mounting systems incorporate advanced engineering approaches that optimize material usage while ensuring structural performance across varying environmental conditions. Their bifacial solar panel ground mounting structures eliminate structural shading and achieve up to 15% increased power generation compared to conventional mounting systems.

Flat roof mounting solutions demonstrate Landpower's expertise in ballasted designs that eliminate roof penetrations while providing reliable structural performance. These systems accommodate varying panel configurations and tilt angles while maintaining consistent performance across diverse commercial and industrial applications.

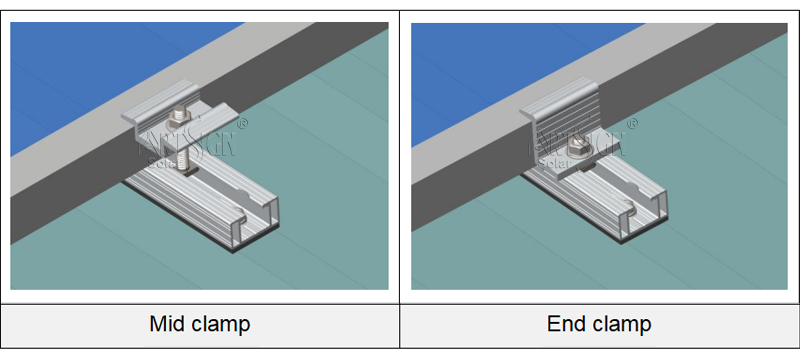

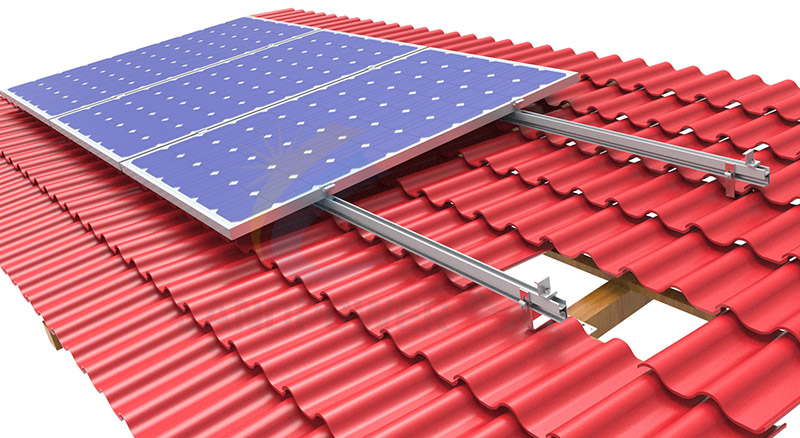

Their pitched roof mounting systems address the complex requirements of residential and commercial sloped installations, incorporating specialized hardware that preserves roof integrity while providing secure panel attachment across multiple roof materials and configurations.

Manufacturing Excellence and Quality Assurance

As a China top Solar Mounting Systems manufacturer, Landpower's production capabilities reflect the sophisticated manufacturing operations required to serve global markets with consistent quality and delivery reliability. Their facilities incorporate advanced fabrication equipment and quality control systems that ensure component precision across high-volume production runs.

The company's manufacturing approach emphasizes material optimization and production efficiency while maintaining strict adherence to international quality standards. Computer-controlled forming and cutting operations enable precise component dimensions that simplify field installation procedures and reduce assembly time requirements.

Comprehensive testing protocols verify structural performance under simulated environmental conditions, including wind uplift forces, thermal cycling, and corrosion exposure. These quality assurance measures ensure reliable long-term performance across diverse geographic regions and climate conditions.

Continuous improvement methodologies incorporate customer feedback and field performance data into manufacturing process optimization, ensuring products evolve to meet changing market requirements and performance expectations.

Engineering Capabilities and Customization Services

Landpower's engineering team addresses complex technical challenges through innovative design solutions that optimize system performance while accommodating project-specific constraints and environmental factors. Their capability to customize mounting systems enables successful deployment across varying installation conditions and regulatory requirements.

Advanced structural analysis software enables optimization of material usage while ensuring compliance with international building codes and environmental load specifications. This technical capability reduces project costs while maintaining structural performance and safety margins throughout system operational lifetimes.

The engineering team collaborates closely with customers to develop solutions that address unique project requirements, including site-specific constraints, environmental considerations, and aesthetic integration needs. This consultative approach ensures optimal system performance and customer satisfaction across diverse application segments.

Market Applications and Global Customer Success

Landpower's mounting systems serve multiple market segments worldwide, each presenting distinct technical requirements and installation challenges that demand specialized expertise and comprehensive support services.

Residential Solar Applications

Residential installations require mounting systems that balance cost-effectiveness with aesthetic integration and long-term reliability. Landpower's residential mounting solutions provide homeowners with reliable solar infrastructure that preserves architectural appearance while enabling substantial energy generation capacity.

The company's pitched roof systems accommodate various residential roofing materials and configurations, incorporating specialized hardware that maintains roof warranty coverage while providing secure panel attachment. Installation efficiency features reduce deployment time and labor costs, enabling competitive project pricing.

Customer satisfaction in residential markets depends heavily on system reliability, aesthetic integration, and minimal maintenance requirements. Landpower's engineering approach ensures mounting systems complement residential architecture while providing decades of dependable performance.

Commercial and Industrial Installations

Commercial applications present unique challenges related to scale, structural requirements, and operational constraints. Landpower's commercial mounting systems address these requirements through enhanced engineering specifications and comprehensive technical support services.

Large commercial installations require mounting systems capable of supporting extensive panel arrays while accommodating building-specific structural limitations and aesthetic requirements. Landpower's scalable mounting solutions provide consistent performance across varying project sizes and complexity levels.

Industrial facilities often involve challenging environmental conditions, including chemical exposure, vibration, and thermal cycling that require enhanced mounting system durability. Landpower's industrial-grade solutions address these demanding operating conditions while maintaining installation efficiency and cost-effectiveness.

Utility-Scale and International Projects

Utility-scale installations demand mounting systems that deliver reliable performance across massive solar arrays while accommodating site-specific constraints and regulatory compliance requirements. Landpower's utility-scale mounting solutions provide proven performance for projects ranging from 50MW to multi-gigawatt developments.

International market expansion requires understanding of diverse regulatory frameworks, environmental conditions, and installation practices. Landpower's global presence demonstrates their ability to adapt products and services to regional requirements while maintaining consistent quality standards.

The company's supply chain management capabilities enable timely delivery to international markets while maintaining cost competitiveness and quality consistency. This operational excellence supports customer satisfaction and long-term market development across multiple geographic regions.

Innovation and Future Market Development

Continued market leadership requires ongoing investment in product development, manufacturing capability enhancement, and customer service excellence. Landpower's research and development initiatives focus on emerging technologies that improve mounting system performance while reducing installation costs and environmental impact.

Current innovation programs include advanced materials research, installation optimization techniques, and integrated monitoring capabilities that enable predictive maintenance and performance enhancement. These technological developments position Landpower advantageously for future market opportunities while addressing evolving customer requirements.

The company's commitment to sustainability encompasses manufacturing processes, supply chain management, and product lifecycle considerations. This comprehensive approach addresses growing market demand for environmentally responsible solar infrastructure solutions.

For comprehensive information about Landpower's solar mounting systems and technical capabilities, visit https://www.landpowersolar.com/