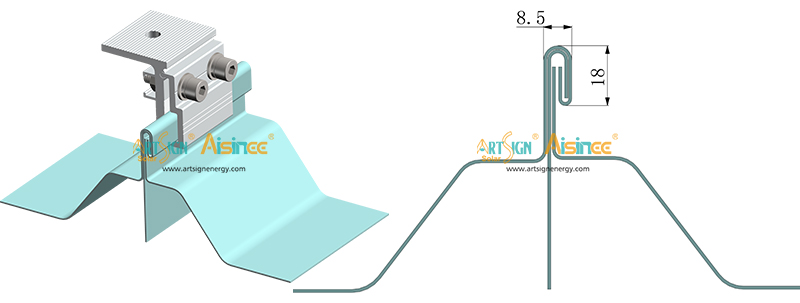

If you’ve ever had the headache of installing solar panels on a metal standing seam roof, you know the biggest worry is the same for everyone: leaks. Once you start drilling holes, it can ruin the waterproof seal.

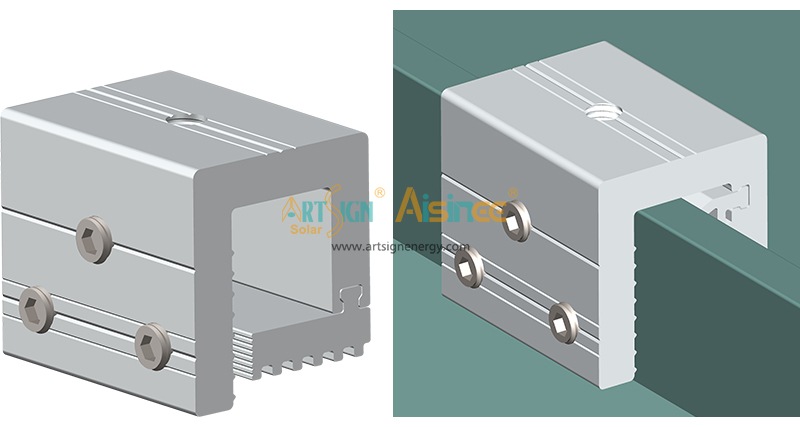

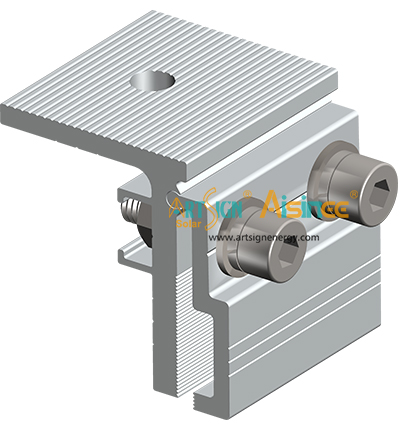

With almost 20 years of experience in this line, we’ve pretty much seen (and solved) every mounting problem out there. We don't just sell mounting hardware; we're a factory with the engineering brains to back it up. That's why we’re so excited to show off one of our best solutions for tin standing seam roofs: our Aluminum Seam Clamp!

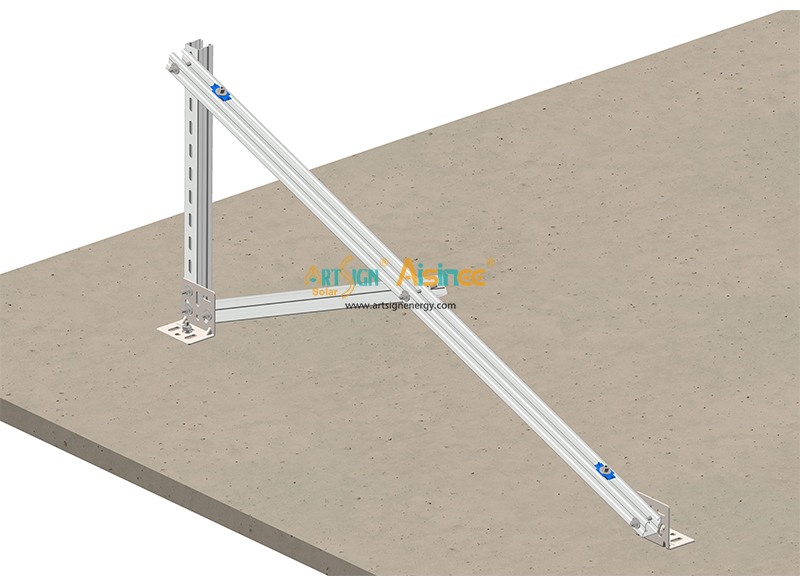

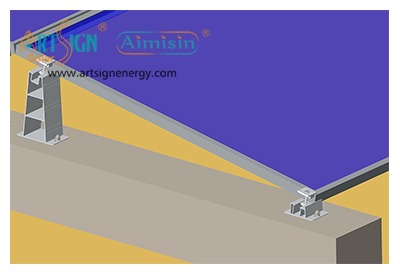

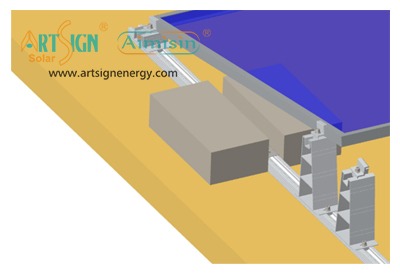

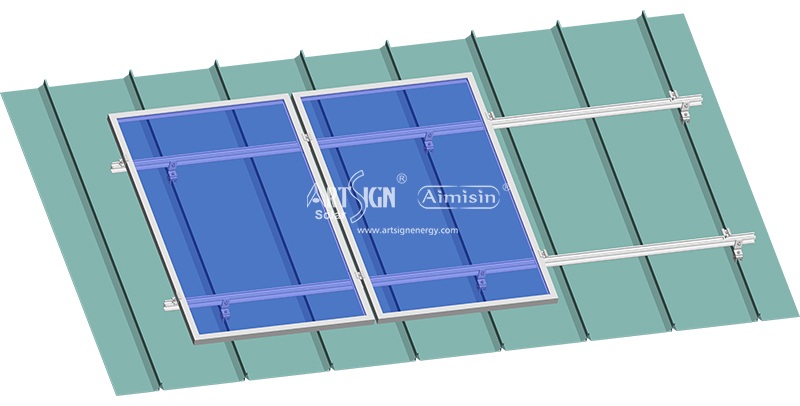

Water proof: No hole on the roof, no water leaks.

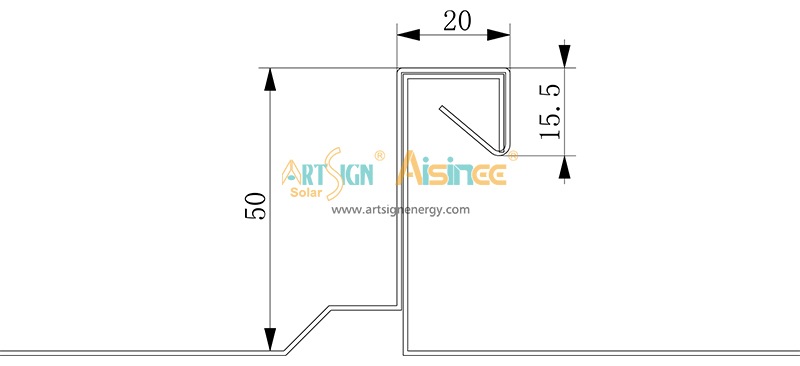

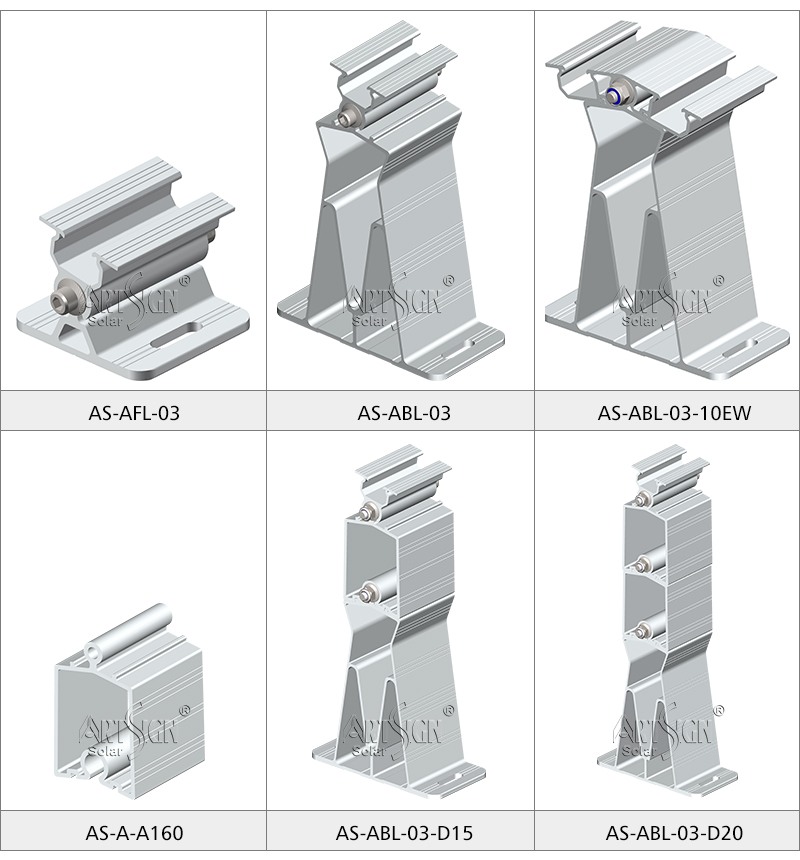

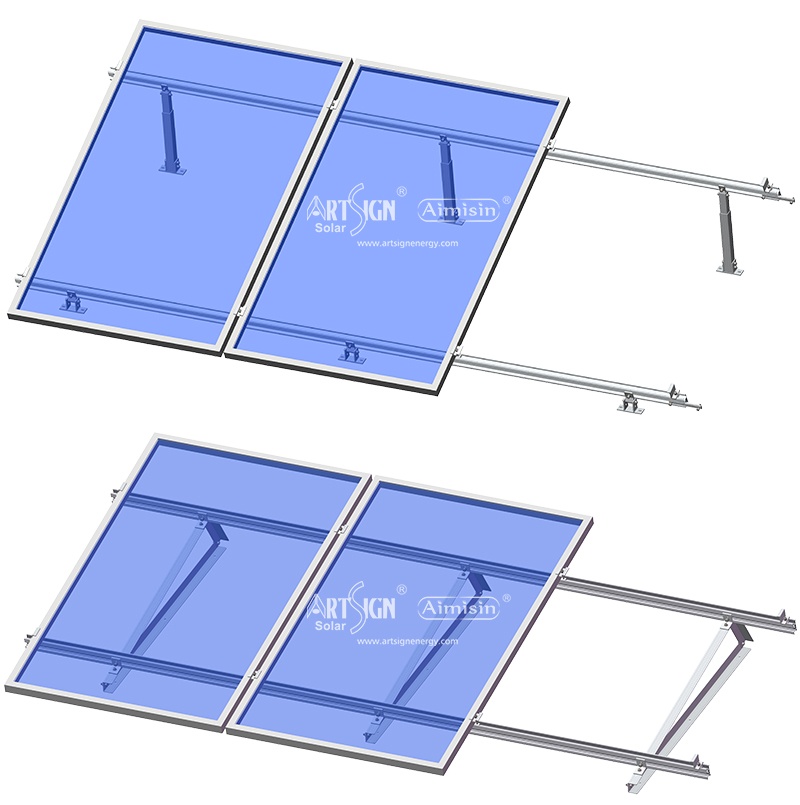

High durability: We make this of high-strength AL6005-T5 Aluminum. It can handle serious weather, from heavy snow to strong winds. You’re guaranteed a long, reliable run for your PV system.

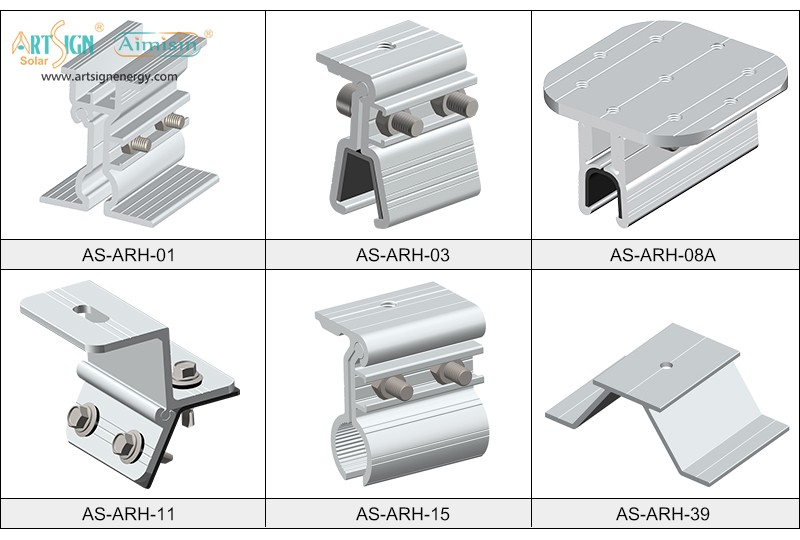

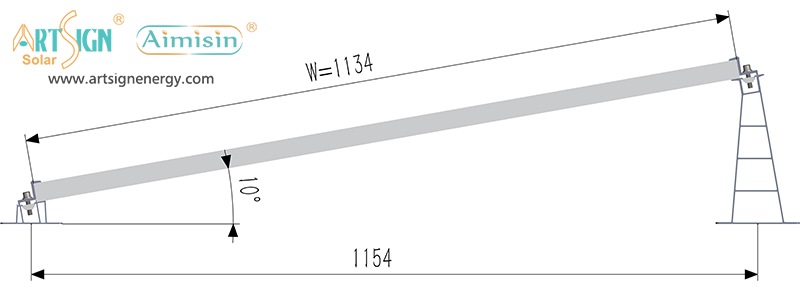

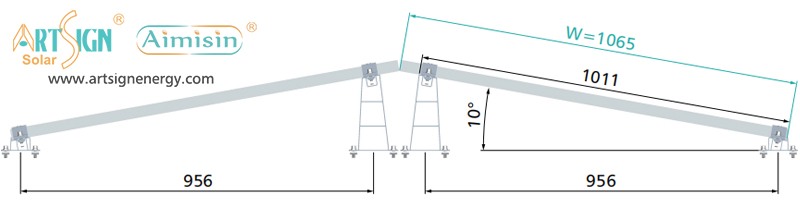

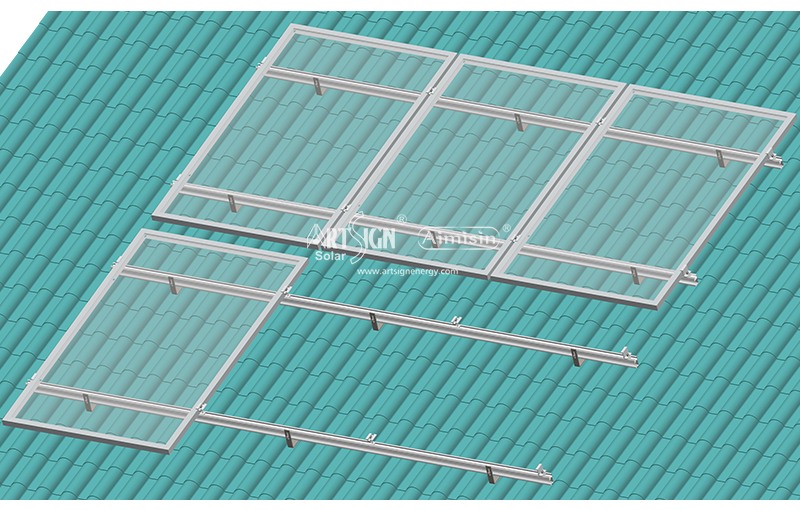

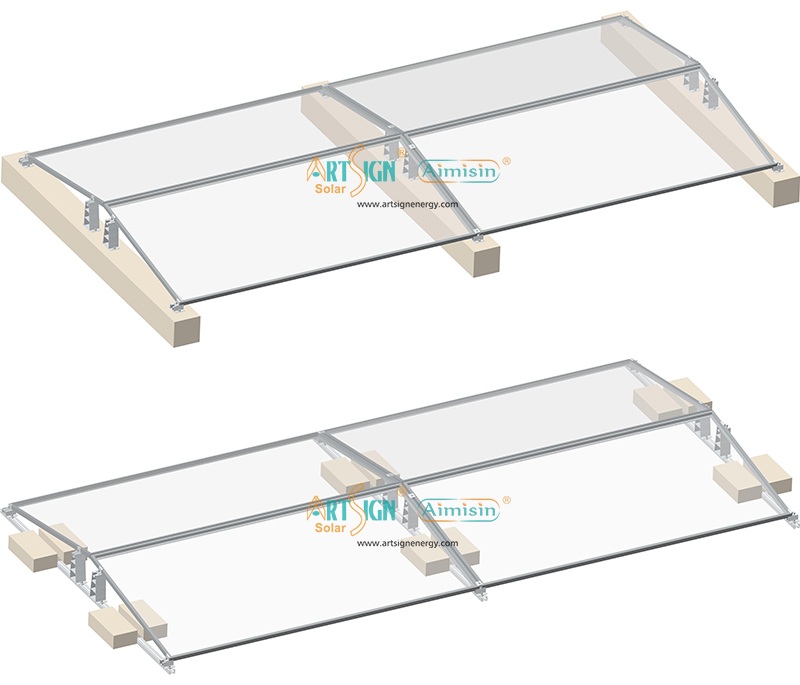

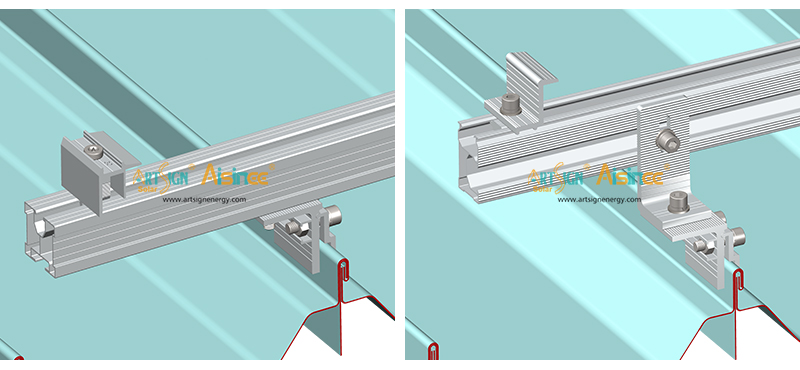

The clamp is highly pre-assembled, which can significantly reduce installation time. And the product is specifically designed for particular roof types, the design ensures a perfect fit and optimal load distribution, guaranteeing a stable, secure, and precise installation.

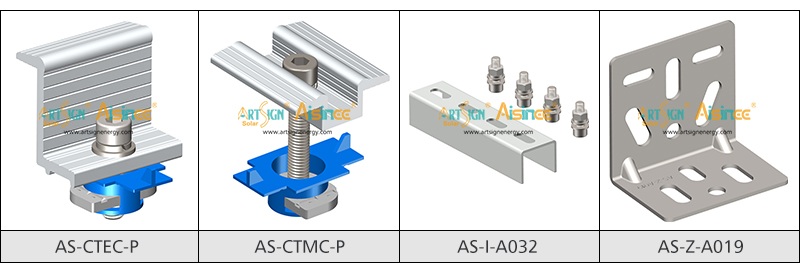

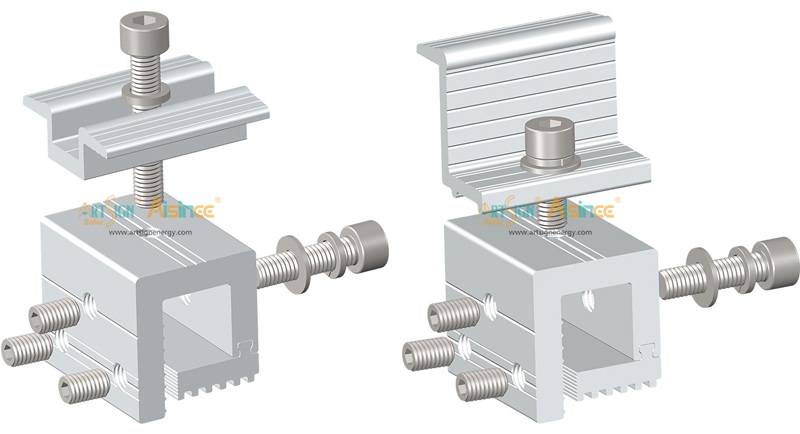

The clamp can be attached directly to rails or used in conjunction with L-feet.

Remember, we're not just a production line; we're a design powerhouse. Our team has the engineering design capability that comes with 20years of focusing on solar mounting. If your project has a weird or unique roof structure, or if you need something nobody else offers, we can customize and develop the exact solution you need.

For any inquiry for solar mounting system, please contact us, E-mail: sales@artsign.net.cn, Whatsapp / Wechat / Skype: +86 18030235875, thank you.